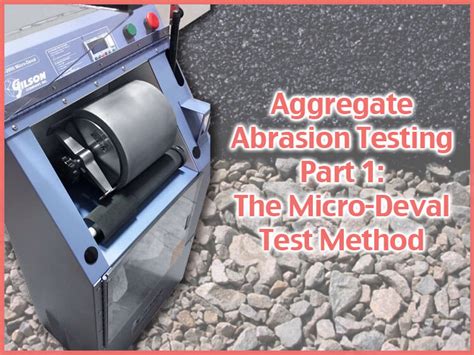

la hardness micro deval test|micro deval testing : purchasers Abrasion testing measures the relative quality and durability of mineral aggregates when subjected to abrasion and impact. There are two popular tests widely used today: Los Angeles (L.A.) Abrasion Test and the Micro-Deval Test. Autoclaves use saturated steam under pressure of approximately 15 pounds per square inch to achieve a chamber temperature of at least 250°F (121°C) for a prescribed .

{plog:ftitle_list}

This technology involves the integration of a radial fan or an air circulation system within the autoclave chamber. The fan facilitates the uniform distribution of air towards the chamber walls, which are cooled by water coils.

Abrasion testing measures the relative quality and durability of mineral aggregates when .Micro-Deval Test: an Alternative to L.A. Abrasion Wu et al. (1998 [2] ) found the Micro-Deval apparatus to be the only commonly used test that had adequate predictive abilities concerning toughness and abrasion resistance.Abrasion testing measures the relative quality and durability of mineral aggregates when subjected to abrasion and impact. There are two popular tests widely used today: Los Angeles (L.A.) Abrasion Test and the Micro-Deval Test.Values derived from both the Micro Deval and the L.A. Abrasion tests offer information about the performance of aggregate in use. This testing offers insight into how asphalt and concrete aggregates will stand up to wear and tear over time.

One widely recognized method of testing the toughness and abrasion resistance of these materials is the Los Angeles (L.A.) Abrasion Test. This detailed exploration will unwrap the complexities, applications, limitations, and an alternative approach to this renowned test.Hardness • Hardness is the aggregate’s resistance to abrasion (wear) • Hardness is an important property for aggregates in pavement surfaces • Tested by LA Abrasion or Micro Deval

For example, slag and certain limestones often show high LA Abrasion loss but perform well on-site. For additional insight, the Micro-Deval test can be used. This test is similar to the LA Abrasion test but employs a smaller drum and spheres.The Los Angeles abrasion test (LA abrasion) is the North American standard for testing toughness (resistance to abrasion and degradation [1]) of construction aggregate or gravel and its suitability for road construction. A comprehensive literature review study has been conducted to establish the relationship between geological parameters (mineralogy, grain size, crystal size, grain shape, and porosity) of rocks and two most common tests: the Los Angeles (LA) test . Tests of resistance to wear and fragmentation are performed in the micro-Deval apparatus (the M DE/DS test) and in the Los Angeles drum (the LA test). Comparative tests demonstrated that the M DE/DS test is more effective than the LA test, as .

The two most common mechanical tests used to investigate the performance of aggregates are the Los Angeles (LA) and micro-Deval (MD) tests. This study reviewed the geological parameters.Micro-Deval Test: an Alternative to L.A. Abrasion Wu et al. (1998 [2] ) found the Micro-Deval apparatus to be the only commonly used test that had adequate predictive abilities concerning toughness and abrasion resistance.Abrasion testing measures the relative quality and durability of mineral aggregates when subjected to abrasion and impact. There are two popular tests widely used today: Los Angeles (L.A.) Abrasion Test and the Micro-Deval Test.Values derived from both the Micro Deval and the L.A. Abrasion tests offer information about the performance of aggregate in use. This testing offers insight into how asphalt and concrete aggregates will stand up to wear and tear over time.

One widely recognized method of testing the toughness and abrasion resistance of these materials is the Los Angeles (L.A.) Abrasion Test. This detailed exploration will unwrap the complexities, applications, limitations, and an alternative approach to this renowned test.

micro deval vs la abrasion

micro deval testing

Hardness • Hardness is the aggregate’s resistance to abrasion (wear) • Hardness is an important property for aggregates in pavement surfaces • Tested by LA Abrasion or Micro Deval For example, slag and certain limestones often show high LA Abrasion loss but perform well on-site. For additional insight, the Micro-Deval test can be used. This test is similar to the LA Abrasion test but employs a smaller drum and spheres.

The Los Angeles abrasion test (LA abrasion) is the North American standard for testing toughness (resistance to abrasion and degradation [1]) of construction aggregate or gravel and its suitability for road construction.

A comprehensive literature review study has been conducted to establish the relationship between geological parameters (mineralogy, grain size, crystal size, grain shape, and porosity) of rocks and two most common tests: the Los Angeles (LA) test . Tests of resistance to wear and fragmentation are performed in the micro-Deval apparatus (the M DE/DS test) and in the Los Angeles drum (the LA test). Comparative tests demonstrated that the M DE/DS test is more effective than the LA test, as .

micro deval aggregate testing

do i need to autoclave tris buffer

For 4~6 minutes rapidly sterilizing. Sterilizing temperature and time can be .

la hardness micro deval test|micro deval testing